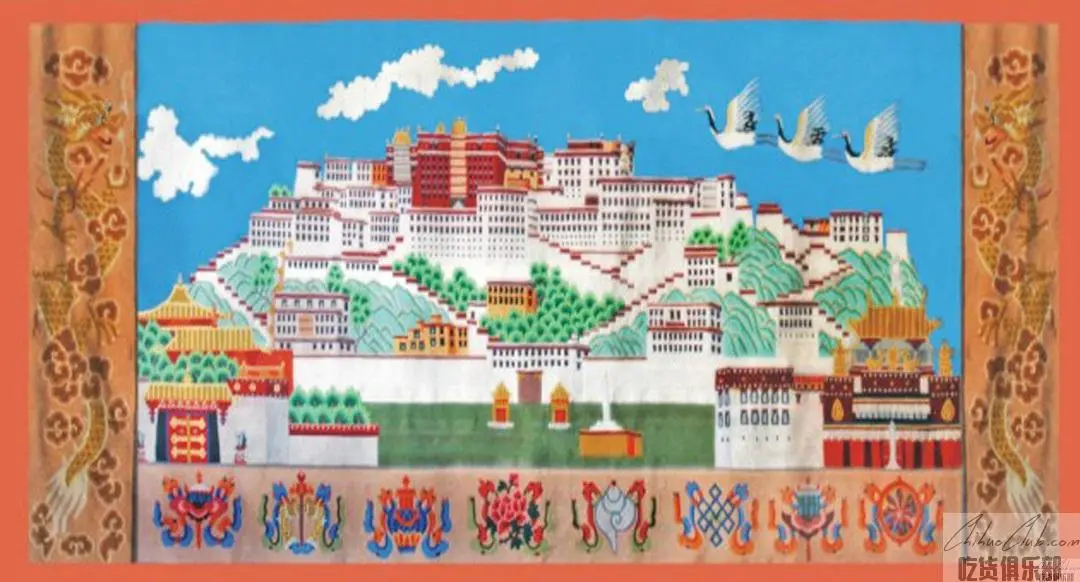

Tibetan Carpet

-

Update date::

-

Date of protection::

-

Protected range:The scope of protection of plaza products of Tibetan carpets is based on the letter from Qinghai Provincial People's Government on requesting the inclusion of Qinghai handmade Tibetan carpets in the protection of national geographical indication products (Qing Zheng Han [2006] No. 47) and the Tibet Autonomous Region People's Government The scope of the blankets listed in the National Geographical Indications Product Protection (Tibetan Letter [2007] No. 65) shall prevail, which is the administrative region under the jurisdiction of Qinghai Province and the administrative region currently under the jurisdiction of the Tibet Autonomous Region.

-

Category:

The Tibetan carpet is made of hand-spun yarn, plant dyeing and hand-woven by the unique knotting method. The carpet surface forms natural horizontal stripes, which look like overlapping layers and distinct layers; the back of the blanket is beautiful, reflecting the rough, simple and natural beauty. Its beautiful pattern, harmonious color, rich hand feeling, flexible, fine texture, comfortable and durable, elegant and elegant, all in one, and today's Persian and Oriental blankets are called the world's three famous carpets.

Technical requirements for quality of Tibetan carpets (1) Qinghai production area. 1. Raw materials: The wool Xining wool produced by the Tibetan sheep in the Tibetan Plateau is the main raw material. 2. Process: raw material → wool yarn production → carpet weaving → finishing → finished product 3. Process requirements: (1) wool yarn production: 1 scouring: raw wool → graded classification → opening loosening → washing wool → washing wool 2 and Hair: The moisture regain rate after the hair reaches 28% to 30%, the mixture is uniform and the oil and water are even. 3 combing, spinning: the yarn count meets the specified requirements, the twist reaches 15 to 17捻/10cm, the joint length is no longer than 2cm, the length of the steamed head is no longer than 5cm, the purlin is uniform, the belly, the thick section, the detail, the thick Details are not allowed. 4 washing line, dyeing: the color after dyeing meets the standard sample, compared with the standard sample, the surface and the cross-section hue are the same, dyed colorless flower, and is evaluated by GB250 "Gray card for assessing discoloration". The color difference is above 3.5. The yarn with the segment dyeing effect should meet the relevant requirements. After dyeing, the skein should be parallel and straight, and there should be no oil stains or grass miscellaneous. (2) Carpet weaving: Shangjing → weaving. The upper warp is required to be evenly arranged, and the total number of warp heads is determined according to the requirements of the production process. The warp threads are not pressed or stacked, the tightness is uniform, the number of passes is evenly arranged during weaving, the weft plates are parallel and uniform, and the dew, dew is not allowed. Weft; to strictly control the thickness, the upper and lower piles must be consistent in length, empty ring blister should not appear on the back of the carpet; the flower pattern should meet the design requirements; the head should be reasonable, no thorns, no misplacement, no mistakes; It should be uniform in thickness and free of flakes; semi-finished products are clean, free from oil, dirt and stains. (3) Finishing: 1 flat blanket: meet the requirements of finished products, suitable for thickness, not too thin and too thick, no gully, knife mark, knife mark, knife flower on the carpet surface, the carpet surface is smooth and clean, no live, tearing. 2 Cut flowers: The depth and width of the cut are consistent with the number of tracks and the depth of the color. The cuts are flush, clear, uniform and smooth, perfectly reflecting the style of the pattern design. 3 Washing blanket: The carpet surface is smooth and smooth, no flounces, the hair is loose and full, the hand feels smooth, the hair tip is sloping in the direction of the hair; no floating hair, mane, watermark, crease; no cross color, bleeding, printing Color; the surface of the carpet is shiny, and the bottom and bottom are clean and flat. 4 finishing: the blanket is horizontal and vertical, without a hanging bottom, concave heart, four corners without white weft, long hair, seamless stitching of the needlework. There are no long hairs and white wefts on the carpet surface, and there is no dirt or oil on the back of the blanket. The buckle is neat. 4. Quality features: (1) Appearance quality characteristics: excellent materials and exquisite craftsmanship; rich and colorful patterns, clear stripes, and strong Tibetan national style; after washing, it looks like brocade and cut after relief. (2) Technical indicators: the number of tufting, the density tolerance of the head is ≤5.0%, the tolerance of the length of the pile is ±10%, the deviation of the blanket size is ≤2.0%, the deviation of the fiber content of the pile yarn is ≤4%, and the flame resistance ( Damage length) ≤ 75mm, light fastness ≥ 3 to 4, dry rubbing fastness ≥ 3 to 4, wet rubbing fastness ≥ 3. (3) Safety requirements: Product safety indicators must meet the relevant regulations of the state for similar products.

Apply to:

Within the scope of protection of plaza products, the producers of the administrative areas under the jurisdiction of Qinghai Province may apply to the Qinghai Provincial Bureau of Quality and Technical Supervision for the use of the “Special Marks for Geographical Indication Products”; Producers of the administrative areas under the jurisdiction of the Tibet Autonomous Region may submit an application to the Quality and Technical Supervision Bureau of the Tibet Autonomous Region for the use of the \"Special Mark for Geographical Indication Products\", which shall be approved by the General Administration of Quality Supervision, Inspection and Quarantine.