Dehua White Porcelain

-

Update date::

-

Date of protection::

-

Protected range:The scope of protection of Dehua White Porcelain GI products is based on the scope of the Dehua County People's Government of Fujian Province on the definition of the scope of protection of Dehua White Porcelain GI products (De Zheng [2006] No. 167). Huaxian County has jurisdiction over the administrative area.

-

Related origin:fujian quanzhoushi dehuaxian dehuaxian-chishuizhen dehuaxian-chunmeixiang dehuaxian-damingxiang dehuaxian-gaidezhen dehuaxian-gekengzhen dehuaxian-guiyangxiang dehuaxian-guobaoxiang dehuaxian-leifengzhen dehuaxian-longmentanzhen dehuaxian-longxunzhen dehuaxian-meihuzhen dehuaxian-nanchengzhen dehuaxian-sanbanzhen dehuaxian-shangyongzhen dehuaxian-shuikouzhen dehuaxian-tangtouxiang dehuaxian-xunzhongzhen dehuaxian-yangmeixiang

-

Category:

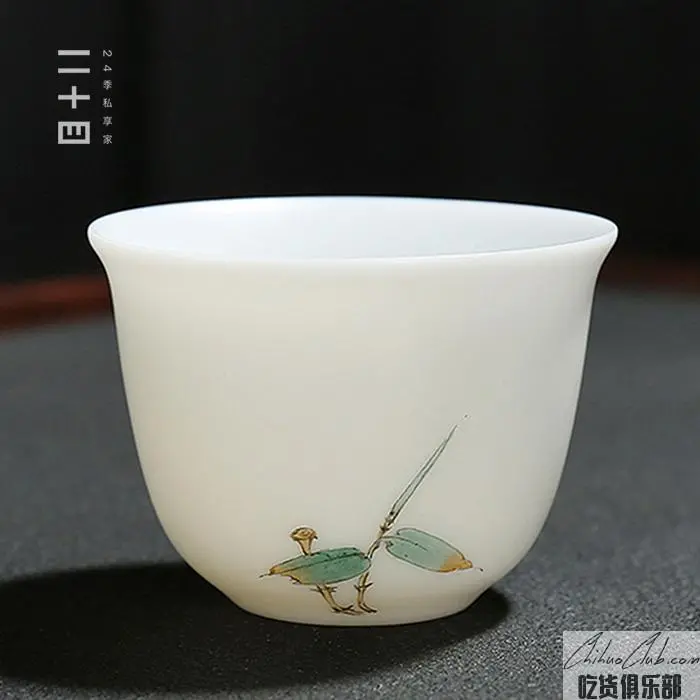

Dehua is one of the three ancient porcelain capitals in China. It is the same as Jingdezhen in Jiangxi and Chaozhou in Guangdong (one is called Fuling in Hunan). Dehua Kiln is a famous porcelain kiln in southern China. It was named after the kiln site in Dehua County. In the history of world ceramics, the word "Chinese white" has become synonymous with Dehua white porcelain. The "Chinese white" original text (BLANC DE CHINE) is a French praise for the Ming Dynasty Dehua white porcelain. They think this is "Chinese porcelain." Top product." Dehua white porcelain is famous for its fine production, firm texture, crystal clear jade, glazed surface like moisturizing, so there are "ivory white", "luck white", "goose white" and so on.

Dehua white porcelain quality technical requirements (1) product categories. Sculpture white porcelain, daily white porcelain. (2) Raw material production. 1. Raw material composition: kaolin, porcelain stone, feldspar, quartz, etc. The main features are low Fe2O3 and TiO2. The chemical composition range is shown in the following table: The chemical composition of the raw material name SiO2Al2O3K2ONa2OCaOMgOFe2O3TiO2 Caustic kaolin ≤68.0≥18.0≥1.5≥0.5≤0.4≤0.2≤0.5≤0.1≥11.0 Porcelain ≤70.0≥13.0≥3.0≥1.5≤3.0≤0.5≤0.2 ≤0.05≤3.0 feldspar ≤66.0≥16.0≥11.0≥2.0≤1.5≤0.5≤0.4≤0.05≤0.5 Quartz ≥98.0≤1.5≤0.05≤0.5 2. Raw material processing: soft material beaten, panned; hard material After being crushed, it is then ball milled, sieved, iron-removed, and aged to form a slime. The billet fineness exceeds 250 mesh and the remaining amount is less than 0.5%, and the plasticity index is greater than 2.5. (3) Forming process. 1. Sculpture white porcelain: using hand molding, grouting and so on. 2. Daily white porcelain: According to different product types, manual forming, mechanical forming, grouting, dry pressing and so on are used. (4) Glazing. 1. Sculpture white porcelain: divided into glaze porcelain and bisque porcelain. The glaze porcelain products are glazed by immersion glaze, glaze, spray glaze, glaze, etc. The glaze layer is thick and thin. 2. Daily white porcelain: According to different product types, glaze methods such as glaze, dip glaze, glaze, spray glaze, etc. are used, and the glaze layer is even and thin. (5) Burning. 1. One-time firing: high temperature firing from 1250 ° C to 1400 ° C. 2. Secondary firing: 800 ° C to 900 ° C low temperature burning or 1250 ° C to 1400 ° C high temperature burning; 1250 ° C to 1400 ° C high temperature glaze burning. (6) Quality characteristics. 1. Appearance characteristics: (1) Glazed porcelain products: pure and pure white, such as fat like jade, delicate and elegant, crystal clear and translucent, glazed water thick, and the porcelain body is closely attached, the light color is like a dragonfly. The sculpture white porcelain lines are long and smooth, deep and round, and the clothes are twisted and twisted to make them light and floating. (2) Sculpture porcelain products: pure white, warm as jade, fine porcelain, elegant and clear, clear lines. 2. Physical and chemical indicators: (1) Water absorption rate: ≤0.5%. (2) Thermal stability: The daily-use porcelain is heat-exchanged from 180 ° C to 20 ° C without cracking. (3) Whiteness: ≥80. (4) Microstructure: quartz crystal content is 7% to 15%, mullite content is 20% to 30%, and glass phase content is 55% to 65%.

Apply to:

Producers within the scope of protection of Dehua White Porcelain GI products may apply to the Dehua County Quality and Technical Supervision Bureau of Fujian Province for the use of the “Special Mark for Geographical Indication Products”, which is approved by the General Administration of Quality Supervision, Inspection and Quarantine.