Fuling porcelain

-

Update date::

-

Date of protection::

-

Protected range:The scope of protection for the geographical indication products of Fuling Porcelain is based on the scope proposed by the People's Government of Liling City of Hunan Province on the Proposal for Defining the Geographical Scope of Geographical Indication Products of Fuling Porcelain (Zheng Zheng Han [2005] No. 120), which is the administrative area of Liling City. Inner Ceramics Technology Industrial Park and Nanqiao Town, Fuli Town, Baitutan Town, Pukou Town, Wangxian Town, Wangfang Town, Dongbao Township, Dongfu Town, Sunjiawan Township, Qiong Town, Chuanwan Town, Shentan Town, Qingshuijiang Township, Dameng Town, Hejiaqiao Town, Jiashu Township, Lishanba Town, Junchu Town, Shiting Town, Shenfugang Town, Banshan Township, Xinyang Township, Xianxia Town, Huangpi 30 townships and sub-district offices of Mouth Town, Fenglin City Township, Guanzhuang Township, Lailongmen Sub-district Office, Huangniwa Sub-district Office, Xishan Sub-district Office and Yangsanshi Sub-district Office are under administrative jurisdiction.

-

Category:

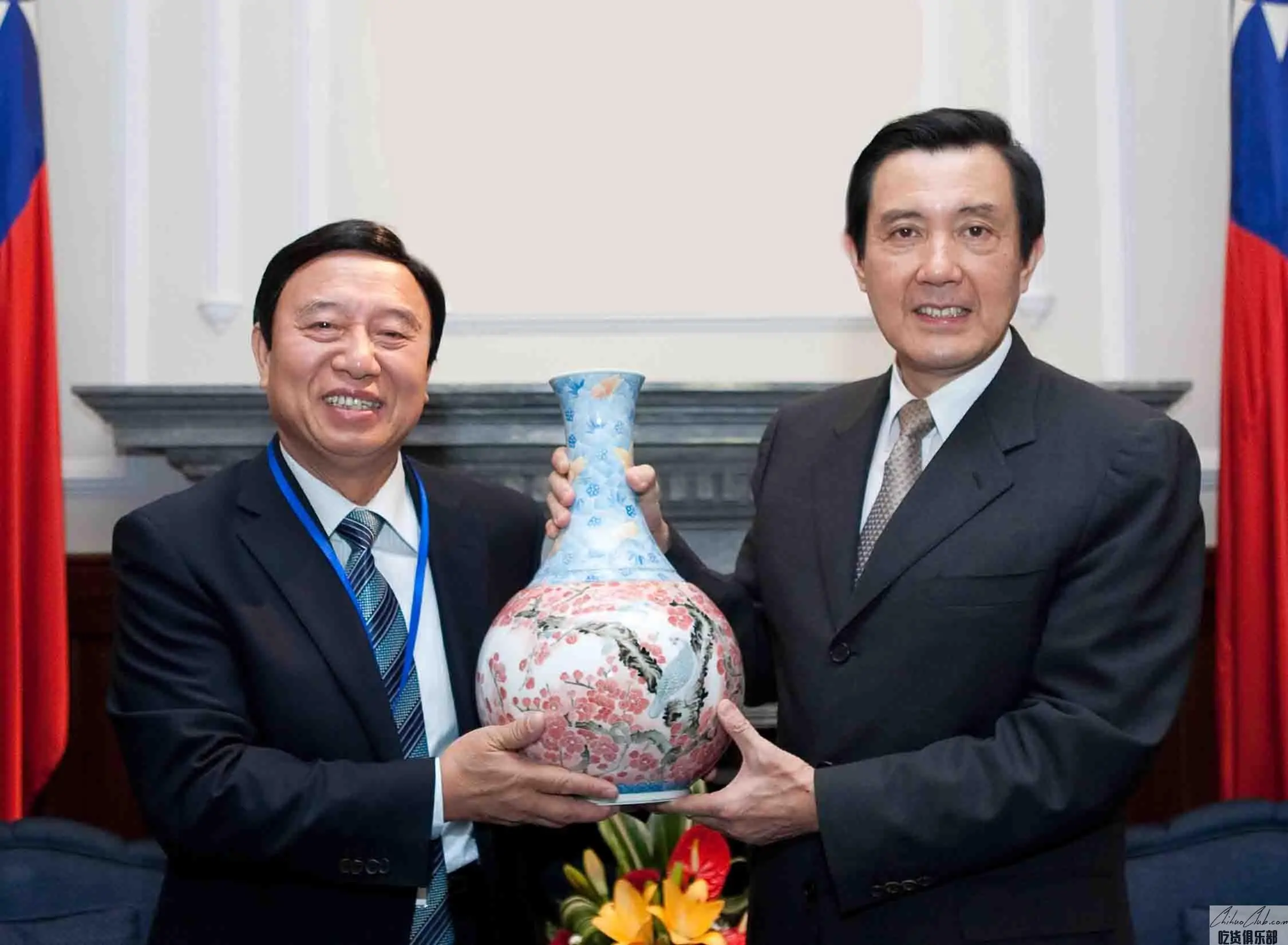

Fuling is the birthplace of the world under the glaze, the rich place of the underglaze porcelain. The Fuling underglaze porcelain, which has been favored by the world, has won the first prize of the Wuhan Persuasion Association and the Nanyang Persuasion Association for its excellent texture, moist and elegant, rich and colorful, and fascinating artistic features. Gold Award, Italy Expo Best Award, Panama Pacific International Exposition Gold Medal.

Fuling porcelain quality technical requirements (a) protection objects. Underglaze multicolored porcelain. (2) Process requirements for billet glaze formulation. 1. Chemical composition of billet: chemical composition SiO2 (%) Al2O3 (%) Fe2O3 + TiO2 (%) CaO + MgO (%) K2O + Na2O (%) IL (%) underglaze multicolored porcelain 64-7219-26 ≤ 0.30 ≤ 13-65-82. Requirements for making porcelain materials: Formulated according to the three-component system of “feldspar-quartz-kaolin”. Porcelain clay and porcelain stone are used as main raw materials, which contain mineral components such as kaolin, quartz and potassium feldspar. The mud, glaze, pigment and flower paper used are all supplied by local mineral resources and local mud glaze processing plants, pigment factories, flower paper factories, etc. or completely homemade. The requirements for formula selection are as follows: the chemical composition of kaolin, porcelain stone, feldspar and quartz for porcelain is as follows: Project kaolin kaolinite feldspar sodium feldspar quartz SiO2 (%) ≥ 52 ≤ 78 ≥ 98.00 Al2O3 content (%)≥35≥13Fe2O3+TiO2 content (%)≤0.40≤0.60≤0.20≤0.20≤0.10TiO2 content (%)≤0.15≤0.20≤0.05≤0.05≤0.03CaO content (%)≤0.80≤0.80MgO content ( %)≤0.80≤0.80K2O+Na2O(%)≥3≥13.00 K2O is greater than 10.00≥10.00 Na2O is greater than 9.00 refractoriness (°C)≥1730 Not specified Not specified Not specified 3. Technical requirements for glazing process: (1) Glaze Chemical composition (feldspar glaze): chemical composition SiO2 (%) Al2O3 (%) Fe2O3 + TiO2 (%) CaO (%) MgO (%) K2O + Na2O (%) IL (%) underglaze multicolored porcelain 68-7610 -14 ≤ 0.200.8-30.2-65-72-4 (2) firing range of glaze: 1360 ° C to 1420 ° C. (3) Production process. 1. Production process: (1) Slurry: material selection, batching, ball milling, sieving and iron removal (multiple times), mud, rough, stale, refined. (2) Glaze: material selection, batching, ball milling, sieving and iron removal (multiple times), and the test is ready for use. (3) Molding: Matching paste and paste with water, stirring, injection molding, die-out, drying, card molding, and standby. (4) Pigment preparation process: material selection, raw material pulverization, compounding, mixing, calcination, coarse crushing, ball milling, drying, grinding, sieving, inspection, and standby. The composite color material is made up of a variety of pigments and fillers. Calcination of different pigments requires firing at different temperatures and atmospheres. According to the different firing process, there are three firing systems, two firing systems and one firing point, so the molding glaze, the prime burning, the color decoration, the glaze burning and the like are also different. Glaze, color, and burning are the three key factors in the production of underglaze porcelain. (5) Forming, color decoration, glaze burning process: 1 production process of one-time firing: rough blank production, color decoration, glazing, high temperature glaze burning, inspection, packaging. 2 two-burning production process: rough blanking, glazing, low-temperature burning, color decoration, spray glaze, high temperature glaze burning, inspection, packaging. 3 three-burning production process: rough blank production, low-temperature burning, color decoration, low-temperature burning, glazing, high-temperature glaze burning, inspection, packaging. 2. Glaze burning process system: three major institutional pressure system atmosphere system temperature system (°C) underglaze multicolored porcelain positive pressure reduction 1360-1420 (four) quality characteristics. Porcelain exquisite, exquisite workmanship, colorful, colorful and unconventional, elegant and bright, smooth and glazed, high whiteness (above 70%), good brightness, good light transmission, high mechanical strength and excellent Chemical stability, good thermal stability (ie, heat exchange at 20 ° C in water at 180 ° C does not crack once). Lead-free cadmium poison, no fading.

Apply to:

The producers within the scope of protection of the geographical indication products of Fuling Porcelain may apply to the Quality and Technical Supervision Bureau of Liling City, Hunan Province for the application of the “Special Mark for Geographical Indication Products”, which shall be approved by the General Administration of Quality Supervision, Inspection and Quarantine.