Daying furs

-

Update date::

-

Date of protection::

-

Protected range:The production area of Daying Fur is the administrative area of 4 towns and towns in Daying Town, Xinyi Township, Encha Town and Jiahui Town of Zaoqiang County, Hebei Province.

-

Category:

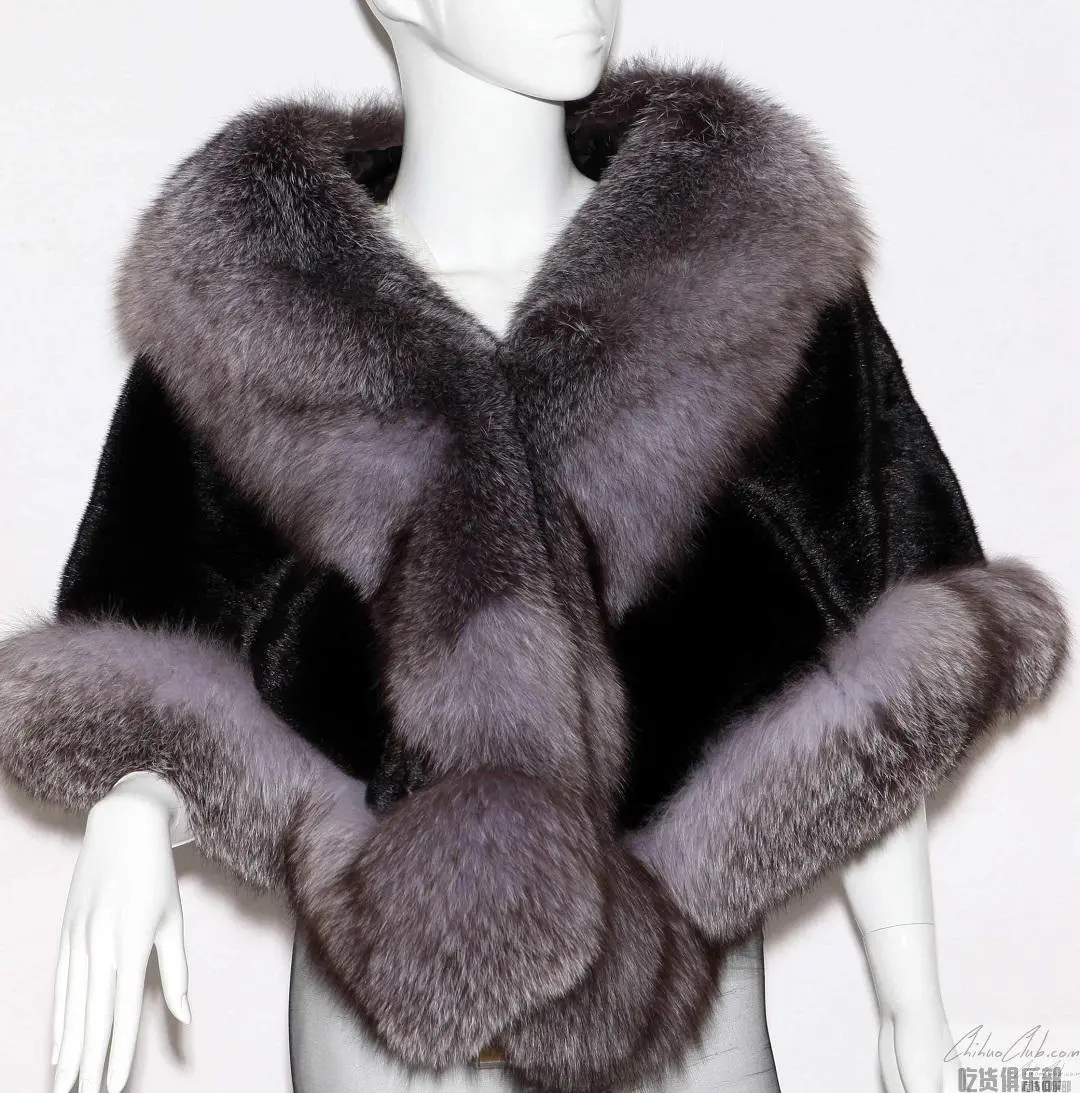

Daying Town is the birthplace of Chinese fur culture. According to legend, Shangqiu invented the craftsmanship process here, which has a history of 3,000 years. At the end of the Yuan Dynasty and the beginning of the Ming Dynasty, the Taiying suede was selected as a tribute to the court. When Zheng He went to the Western Seas, the Daying suede and the embroidered porcelain of Jingdezhen and the porcelain of Jingdezhen crossed the sea and spread the world. The Taiying suede skin is soft, eye-catching, workmanship, style, and color coordination.

During the late Qing Dynasty and the early Republic of China, Daying Mink reached the peak of development. Here, the shops are full of people, and they are full of prosperity. Leather goods merchants from all over the country gathered here, selling and buying cooked food. During the Qing Daoguang years, merchants from more than ten countries including Britain, Russia, Japan and Holland had warehouses in the big camp. The infiltration of the three thousand years of fur culture, the ancestors of various generations of handicrafts, so that the town of Daying is connected with the blood of the fur, its deep suede culture has nowhere in the country.

Technical requirements for the quality of the large camping skin 1. Raw material skin requirements 1. Mink skin: shiny, no defects, needles are flush. 2. 3. Suede: The density of the plush is large, the color is pure, and there is no broken needle hair. The above raw material skin is made of a regular season skin. Second, the suede system 1. Process: soaking → shaving → degreasing → softening → pickling → tanning → drum → refueling → kicking → widening → shaving → dry cleaning → finishing. 2. Consistent. (2) Shaving: It is required to be finished by hand to achieve uniform and complete skin and no damage. (3) Degreasing: The nitrate used for degreasing is produced in the production area. (4) Softening: Softening is carried out by steam heating, the temperature is maintained at 31 ° C to 33 ° C, and the softening time is 12 hours to 16 hours. (5) Pickling: The nitrate used for pickling is produced in the production area. (6) Tanning: The aluminum oil was combined with the hydrazine method, and the pH was adjusted to 3.8 to 3.9 after soaking for 4 hours in a tanning solution at 35 ° C to 38 ° C. (7) Drum: Dry with hibiscus until the water content is 20% to 30%, then stretch and stretch. (8) Refueling: Refuel with a kicking oil from 31 ° C to 33 ° C for 110 minutes to 130 minutes. Third, the quality characteristics 1. Sensory features: no sebum and chemical taste, soft texture, fine and soft hair, soft and warm. (1) mink skin: the skin type is complete, the plush is flat and flexible, the hair color is pure and bright, and the back belly is basically the same; the length of the needle fluff is moderate, the needle hair is covered with good fluff; the plate quality is good. (2) Fox skin: the leather type is complete, the plush is thick and dense, the needle hair is complete and flexible, the hair is fluffy, the color is uniform, the light is smooth, and the leather board is fine and tough. (3) suede: the skin type is complete, the plush is abundant, the needles are complete, the fluff is clear, the color is smooth, and the board is good. 2.

Apply to:

Producers within the scope of the production area of Daying Furnace may submit an application for the use of the “Special Mark for Geographical Indication Products” to the Quality and Technical Supervision Bureau of Zaoqiang County of Hebei Province. It shall be reviewed by the Hebei Provincial Bureau of Quality and Technical Supervision and reported to the General Administration of Quality Supervision, Inspection and Quarantine for approval. . The testing organization of Daying Furs is selected by the Hebei Provincial Bureau of Quality and Technical Supervision in the testing institutions that meet the qualification requirements.